YAK25 OTI

230 VAC GEAR MOTOR FOR INTENSIVE USE WITH INTEGRATED CONTROL UNIT, VIRTUAL ENCODER AND INVERTER

230 Vac

Up to 2500 kg

512 transmitters storable inside the receiver

Industrial use

The inverter technology allows the speed of the motor to be gradually varied, during both acceleration and deceleration, as well as guaranteeing a more precise adjustment of the gate movement phases and a greater anti-crushing safety

Oil lubricated motors guarantee the maximum lifespan and high performances

Intelligent power control system that allows obtaining dynamic data through a precise calculation of the thrust. The system is able to locate any critical points and adjust the torque accordingly in relation to actual requirements and according to measured performance

Encoder signal recreated by the control unit beginning with the measurements of electric motor operation parameters. It is possible to manage slowing optimally and trace gate travel while providing the torque data in relation to its position to guarantee maximum safety

YAK25 OTI

230 Vac | three-phase, intensive use

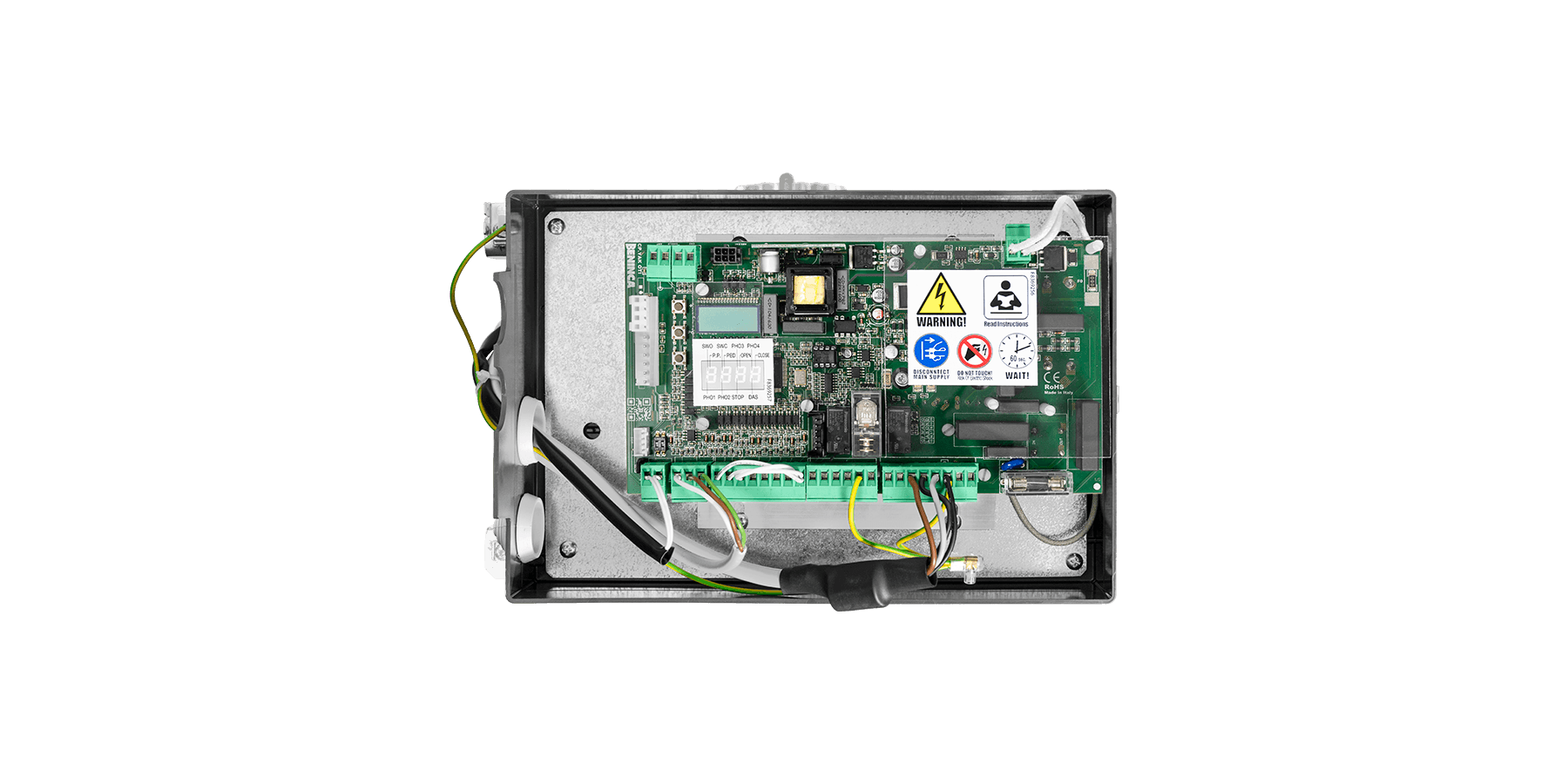

230 Vac gear motor for intensive use with integrated control unit, virtual encoder and inverter | Self-ventilated motor for more intense use | Oil lubricated metallic gear box to ensure maximum performance even at low temperatures | The main control unit, located in the top part of the motor and with integrated inverter, makes it possible to calculate the position of the motor starting from the measurement of current intensity on the electric motor (virtual encoder) | The virtual encoder allows proper management of the slowing-down phases, movement tracking (STC system), and torque management in relation to the position of the gate, which guarantees maximum safety | The inverter technology allows the speed of the motor to be gradually varied, during both acceleration and deceleration, as well as guaranteeing a more precise adjustment of the gate movement phases and a greater anti-crushing safety | Adjustable speed from 10 to 24 m/min according to gate weight | Safety sensor that stops the motor power supply during release operations | External metal casing with the possibility to install PUPILLA/PUPILLA.T photocells (as accessory) | Receiver ONE.2WB is supplied | Metal release lever

Raised foundation plate included. Height 32 mm. Floor fixing distance 280×170 mm, no. 4 Ø 11 mm, motor fixing distance 269×106 mm n.4 M10