WAVE 230

230 Vac

This function automatically adjusts the operational parameters for simplifying the system’s installation and testing operations

512 transmitters storable inside the receiver

Control unit that manages the encoder for maximum precision during the automation manoeuvring steps

This is used to set the number of cycles after which the required maintenance of the system is signaled

The inverter technology allows the speed of the motor to be gradually varied, during both acceleration and deceleration, as well as guaranteeing a more precise adjustment of the gate movement phases and a greater anti-crushing safety

Compatibility with Advantouch device. The system allows a simplified management of transmitters and receivers, with the possibility of managing lists by deleting or storing transmitters in an easy and quick manner

This allows a code to be entered for protection of the control unit programming, to prevent access to menus and modification of parameters

Intelligent power control system that allows obtaining dynamic data through a precise calculation of the thrust. The system is able to locate any critical points and adjust the torque accordingly in relation to actual requirements and according to measured performance

Encoder signal recreated by the control unit beginning with the measurements of electric motor operation parameters. It is possible to manage slowing optimally and trace gate travel while providing the torque data in relation to its position to guarantee maximum safety

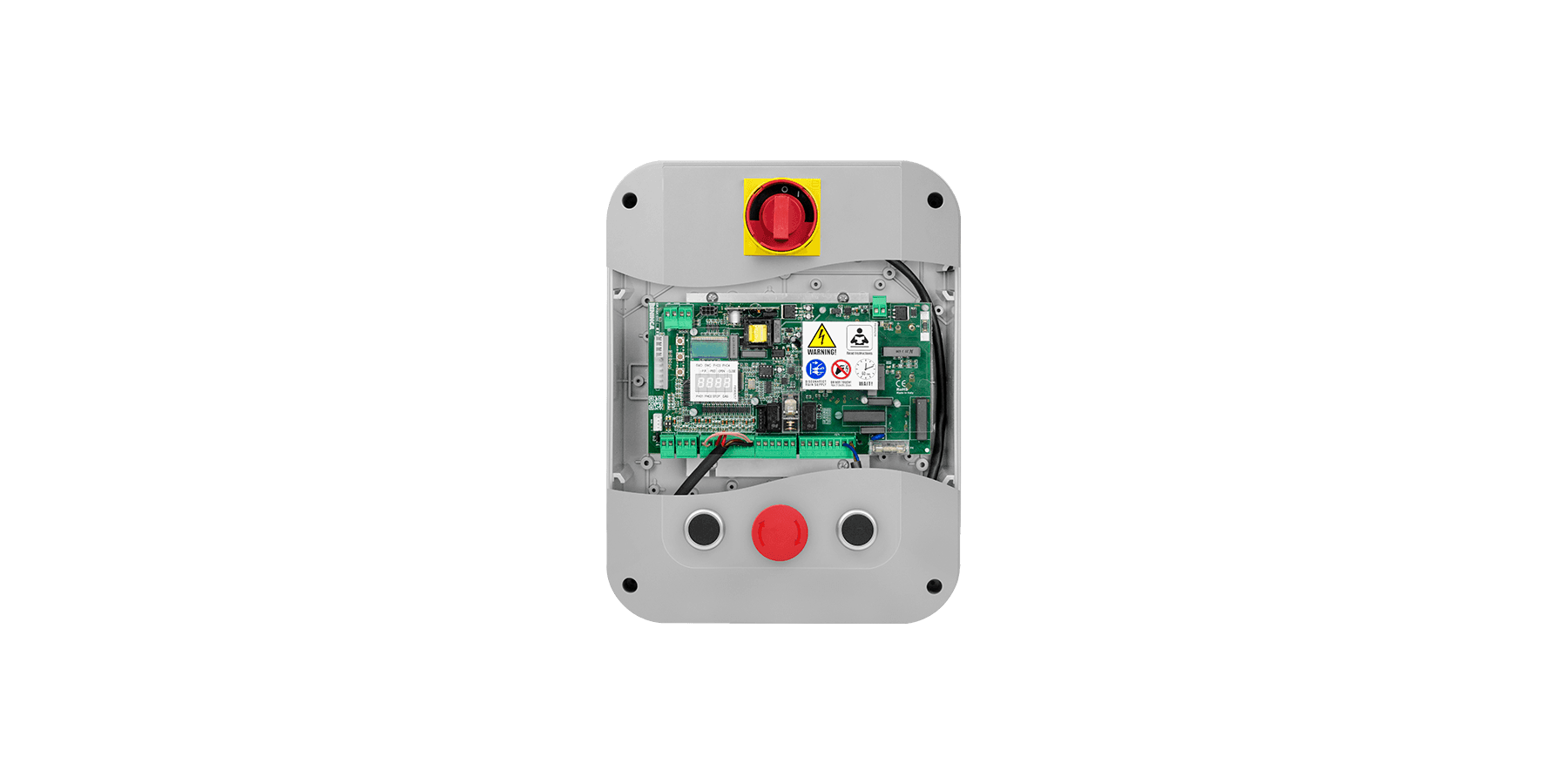

WAVE 230

APPLICATION

1 actuator of the VN series for sectional and rolling doors

CONTROL UNIT POWER SUPPLY

100÷250 Vac – 50/60 Hz

MOTORS POWER SUPPLY

230 Vac

MAIN FUNCTIONS

Integrated LCD display | ONE2.WI model 433.92 MHz radio receiver provided as standard equipment | Removable terminal boards | Automatic, semi-automatic and deadman’s logic | Motor limit switch inputs | Predesigned for connection to absolute encoder and quick wiring (VN “ESW” motors) | Autosetting of operating parameters | Open, close, step by step, pedestrian and stop inputs | Input for N.C or 8K2 sensitive edge | Input for safety sensor | no. 2 photocell inputs configurable as active in opening-closing or in closing phases | Output configurable as gate open indicator, service light, area light | Photocell testing ouput | Second radio channel output | Electronic torque adjustment with automatic calculation for each point in the stroke (STC SYSTEM) | Anti-crushing safety thanks to amperometric obstacle detection | Adjustable slow-downs | Advantouch system to configure parameters and manage radio transmitters | Integrated inverter | Virtual encoder | Number of maneuvers | Programming access password | Maintenance warning