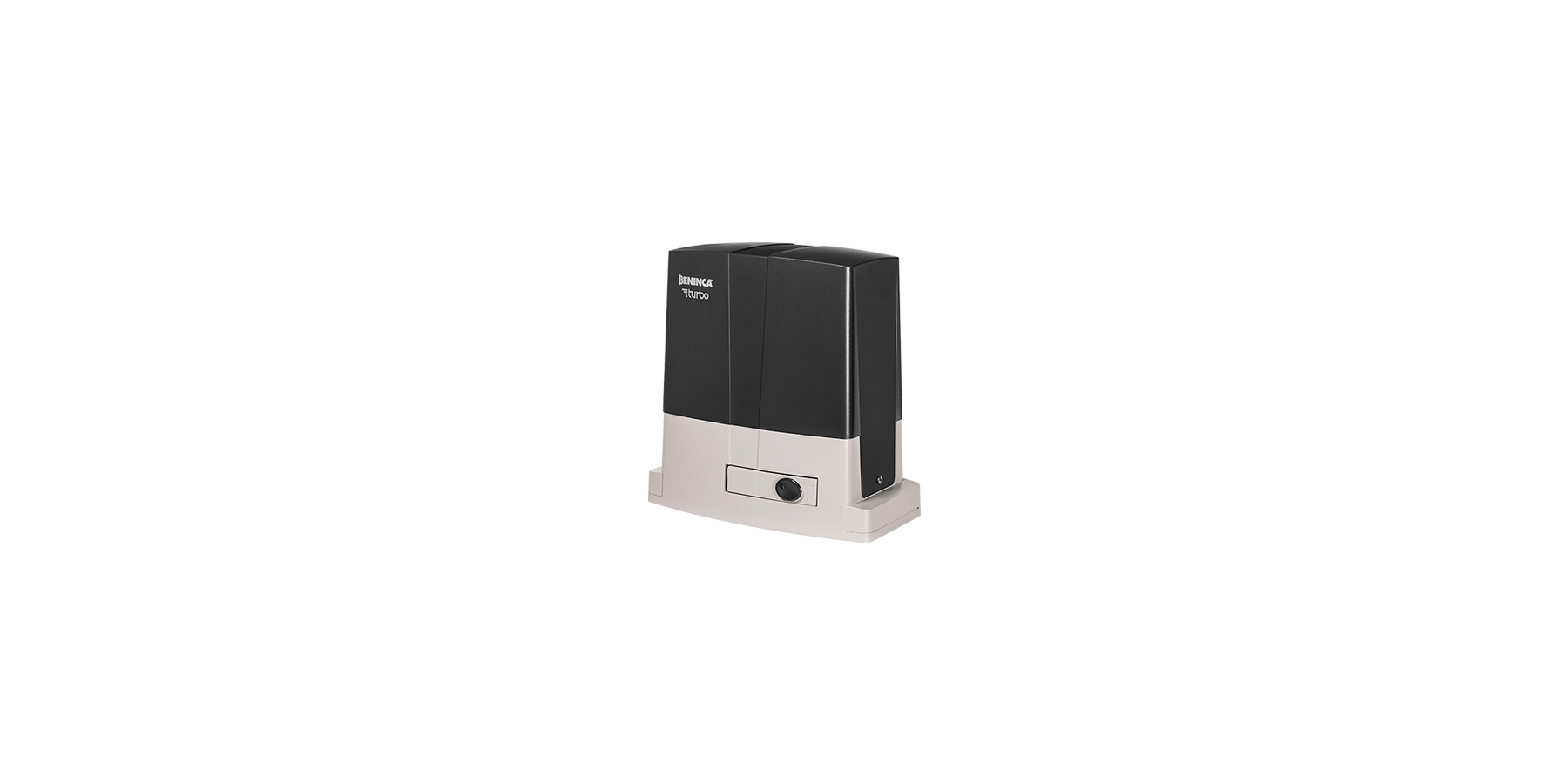

BULL624 TURBO

FAST 24 VDC GEAR MOTOR FOR INTENSIVE USE WITH INTEGRATED CONTROL UNIT AND VIRTUAL ENCODER

24 Vdc

Maximum maneuver speed is 25,5 m/min

Up to 600 kg

433.92 MHz Receiver equipped exclusively with Advanced Rolling Code (ARC)

512 transmitters storable inside the receiver

Commercial use

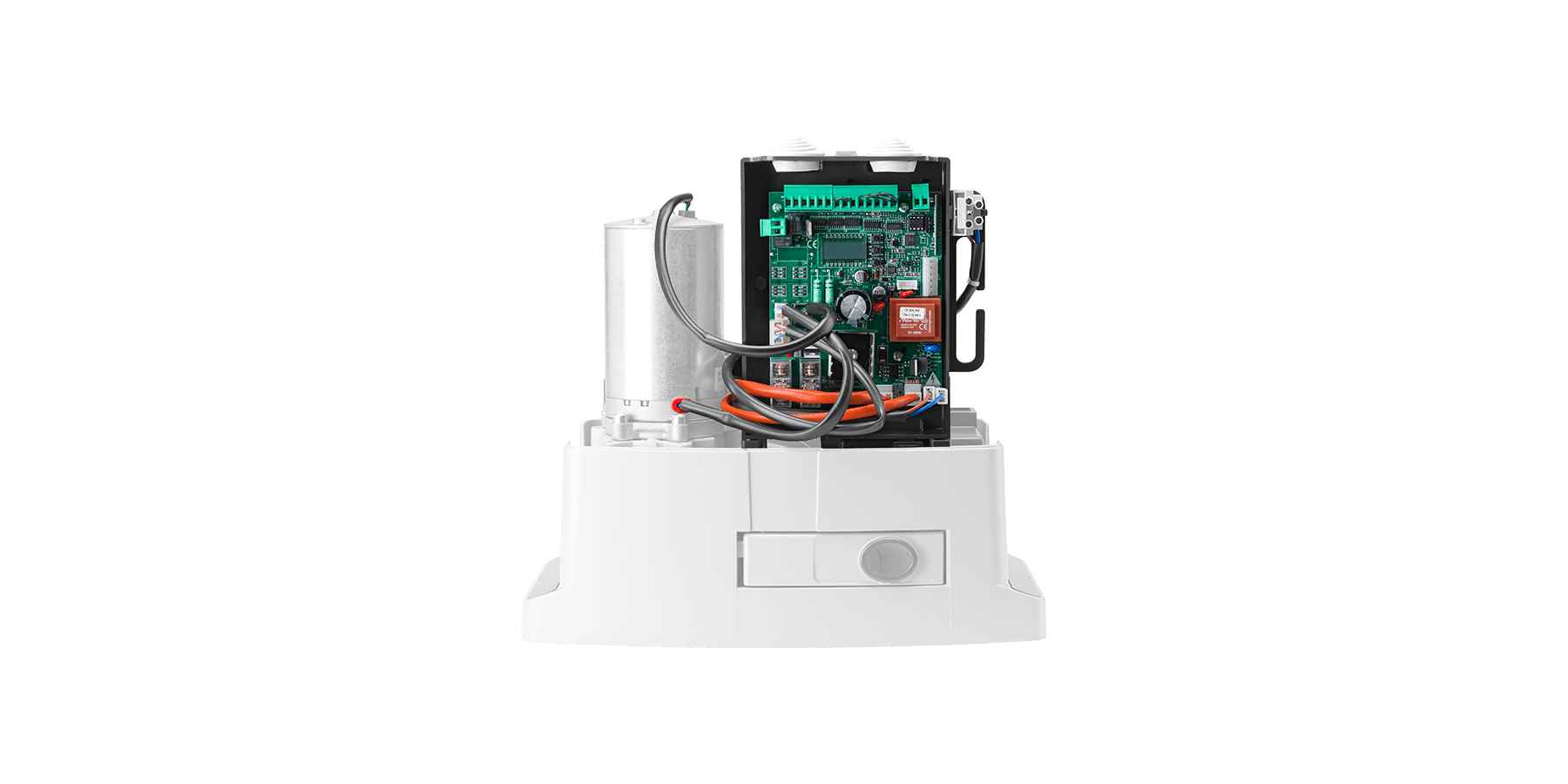

Control unit that manages the encoder for maximum precision during the automation manoeuvring steps

This is a protocol for connection with KNX home automation systems by connection of the X.BE card (optional)

Intelligent power control system that allows obtaining dynamic data through a precise calculation of the thrust. The system is able to locate any critical points and adjust the torque accordingly in relation to actual requirements and according to measured performance

Gear motor with opening speed higher than standard values

Encoder signal recreated by the control unit beginning with the measurements of electric motor operation parameters. It is possible to manage slowing optimally and trace gate travel while providing the torque data in relation to its position to guarantee maximum safety

BULL624 TURBO

24 Vdc | intensive use

Fast 24 Vdc gear motor for intensive use with integrated control unit and virtual encoder | Switching power supply 115/230 Vac which reduces energy consumption and ensures a long lifespan of the actuator | The main control unit, on the top part of the motor, makes it possible to facilitate the wiring procedure and also to calculate the position of the motor starting from the measurement of instantaneous speed (virtual encoder) | The virtual encoder allows proper management of the slowing-down phases, movement tracking (STC system), and torque management in relation to the position of the gate, which guarantees maximum safety | Self-programming with the radio transmitter can be activated at the first installation | Practical cableguides | Maximum performance and speed (25.5 m/min with 600 kg) | Anti-crushing system with amperometric obstacle detection | Safety sensor that stops the motor power supply during release operations | Designed for connection to the X.BE module to integrate the device into KNX home automation systems | Convenient compartment for 2 mod. DA.BT2 2.1 Ah batteries | Metal release lever | Option to operate opposed sliding gates using the SIS accessory

325x100x5 mm, installation template included, motor spacing 300×75 mm, 4 holes Ø 9 mm