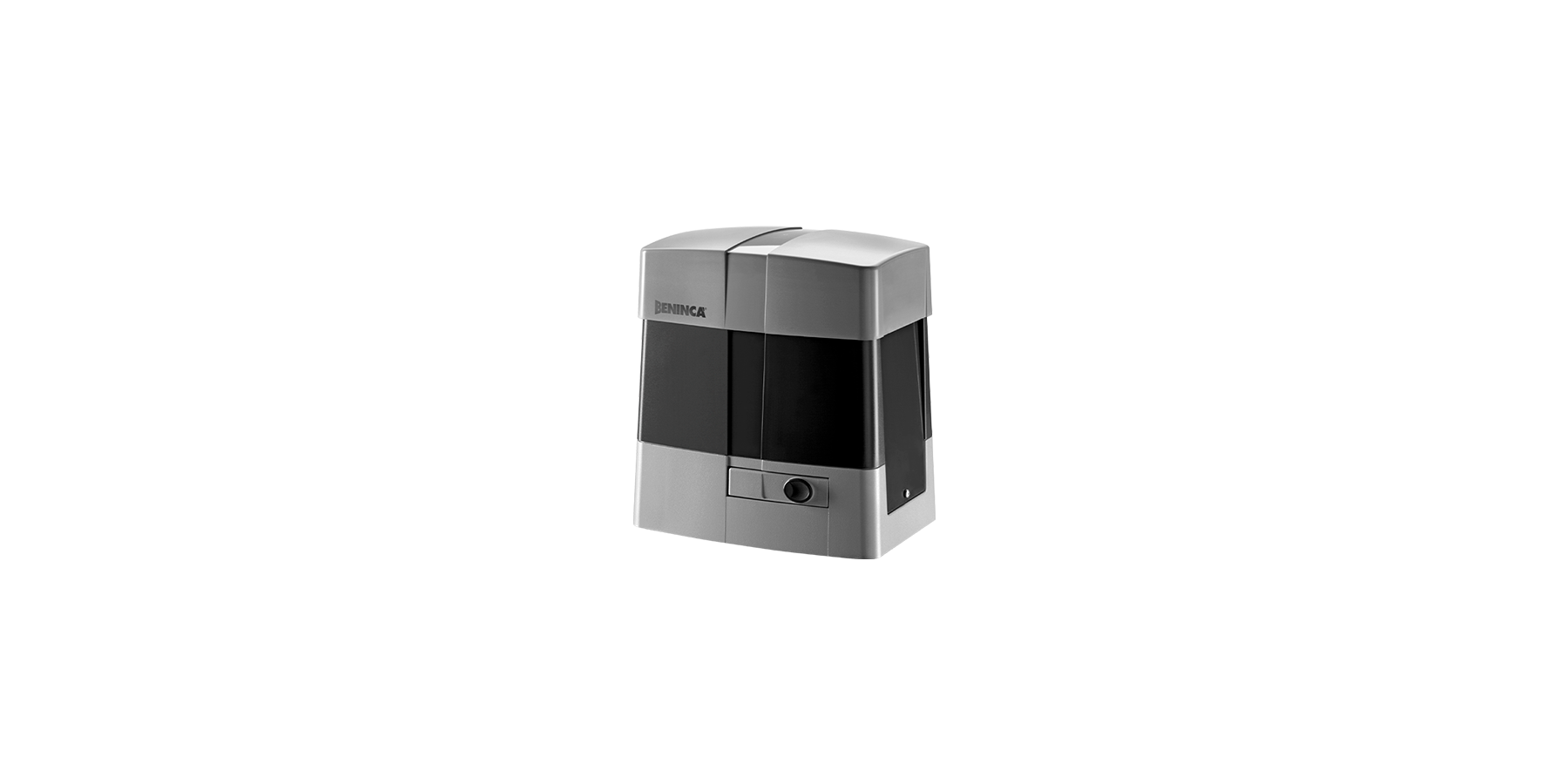

BULL1524

24 VDC GEAR MOTOR FOR INTENSIVE USE WITH INTEGRATED CONTROL UNIT AND VIRTUAL ENCODER

Up to 1500 kg

433.92 MHz Receiver equipped exclusively with Advanced Rolling Code (ARC)

2048 transmitters storable inside the receiver

64 transmitters storable inside the receiver

Commercial use

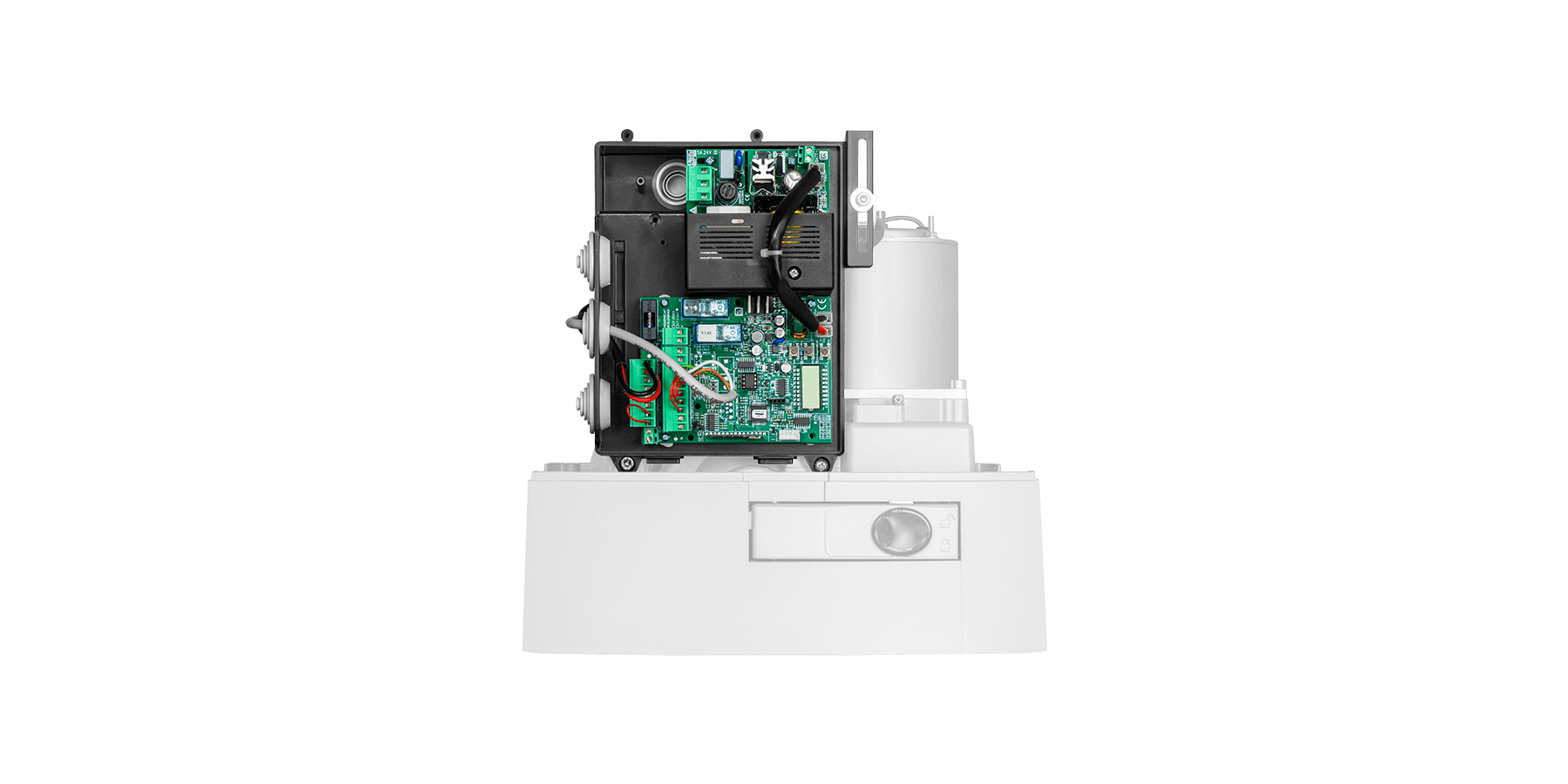

Intelligent power control system that allows obtaining dynamic data through a precise calculation of the thrust. The system is able to locate any critical points and adjust the torque accordingly in relation to actual requirements and according to measured performance

Encoder signal recreated by the control unit beginning with the measurements of electric motor operation parameters. It is possible to manage slowing optimally and trace gate travel while providing the torque data in relation to its position to guarantee maximum safety

BULL1524

24 Vdc | intensive use

24 Vdc gear motor for intensive use with integrated control unit and virtual encoder | Switching power supply 100÷250 Vac which reduces energy consumption and ensures a long lifespan of the actuator | Very intensive use, ideal for condominium applications | Anti-crushing system with amperometric obstacle detection | The control unit makes it possible to calculate the position of the motor starting from the measurement of instantaneous speed (virtual encoder) | The virtual encoder allows proper management of the slowing-down phases, movement tracking (STC system), and torque management in relation to the position of the gate, which guarantees maximum safety | Fast and easy to install, with the self-programming function through the radio transmitter, activation is possible immediately after installation | Option to operate opposed sliding gates using the SIS accessory and in case of power failure with the built-in battery charger accessory | Metal release lever

Foundation plate with anchor bolts included. Motor and floor fixing distance 269×106 mm n.4 Ø 12 mm