BISON25 OTI

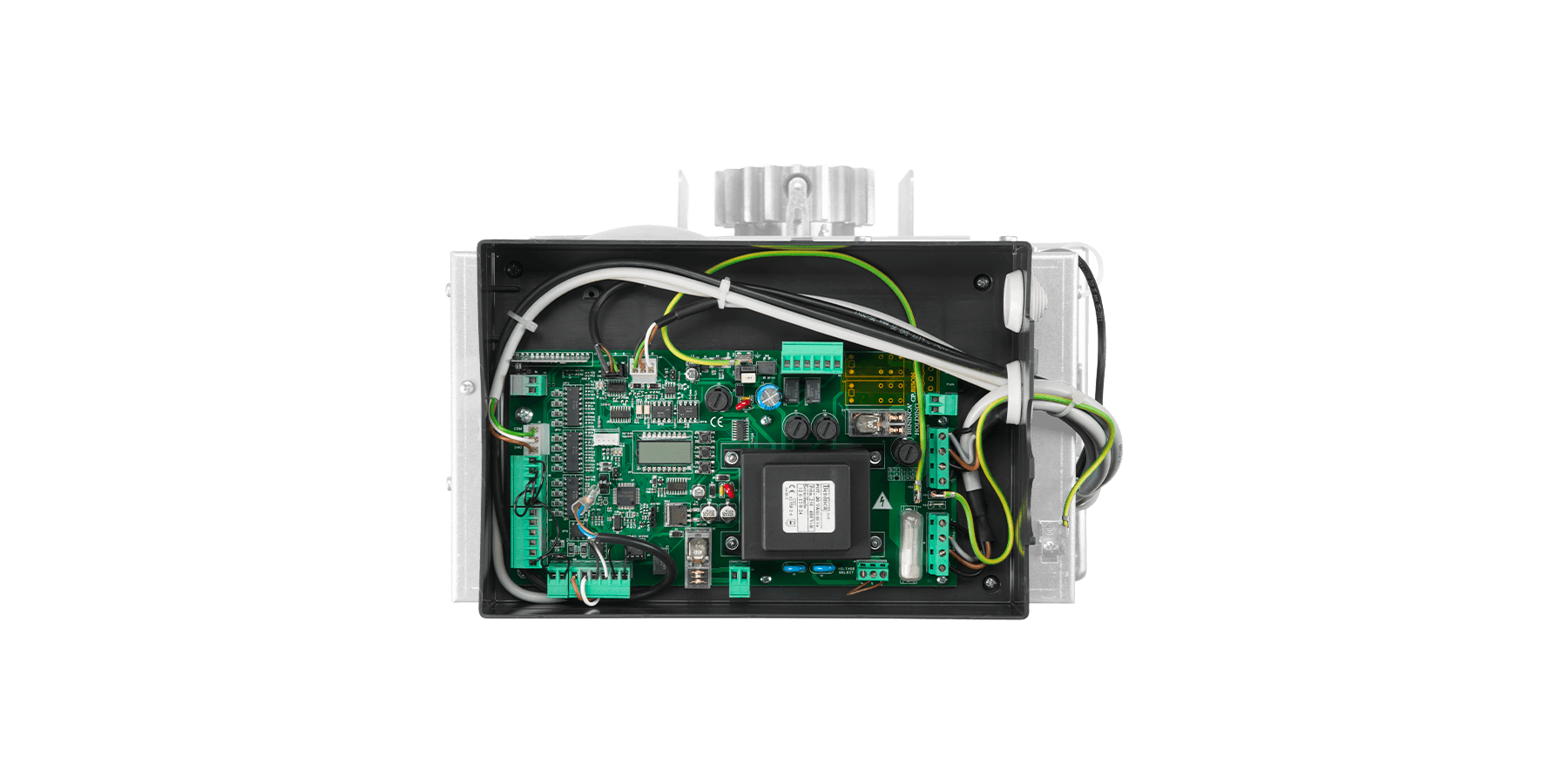

230 VAC GEAR MOTOR FOR INTENSIVE USE WITH INTEGRATED CONTROL UNIT, ENCODER AND INVERTER

230 Vac

Up to 2500 kg

64 transmitters storable inside the receiver

Control unit that manages the encoder for maximum precision during the automation manoeuvring steps

Industrial use

The inverter technology allows the speed of the motor to be gradually varied, during both acceleration and deceleration, as well as guaranteeing a more precise adjustment of the gate movement phases and a greater anti-crushing safety

Oil lubricated motors guarantee the maximum lifespan and high performances

BISON25 OTI

230 Vac | three-phase, intensive use

230 Vac gear motor for intensive use with integrated control unit, encoder and inverter | Self-ventilated motor for more intense use | The encoder device ensures precision in the gate moving phases | Full metal mechanics and oil lubrication with maximum efficiency even at low temperatures | Casing protective treatment and paint | The inverter technology allows the speed of the motor to be gradually varied, during both acceleration and deceleration, as well as guaranteeing a more precise adjustment of the gate movement phases and a greater anti-crushing safety | Optional built-in FTC.S photocells, available as accessory

Foundation plate with anchor bolts included. Motor and floor fixing distance 269×114 mm n.4 Ø 12 mm